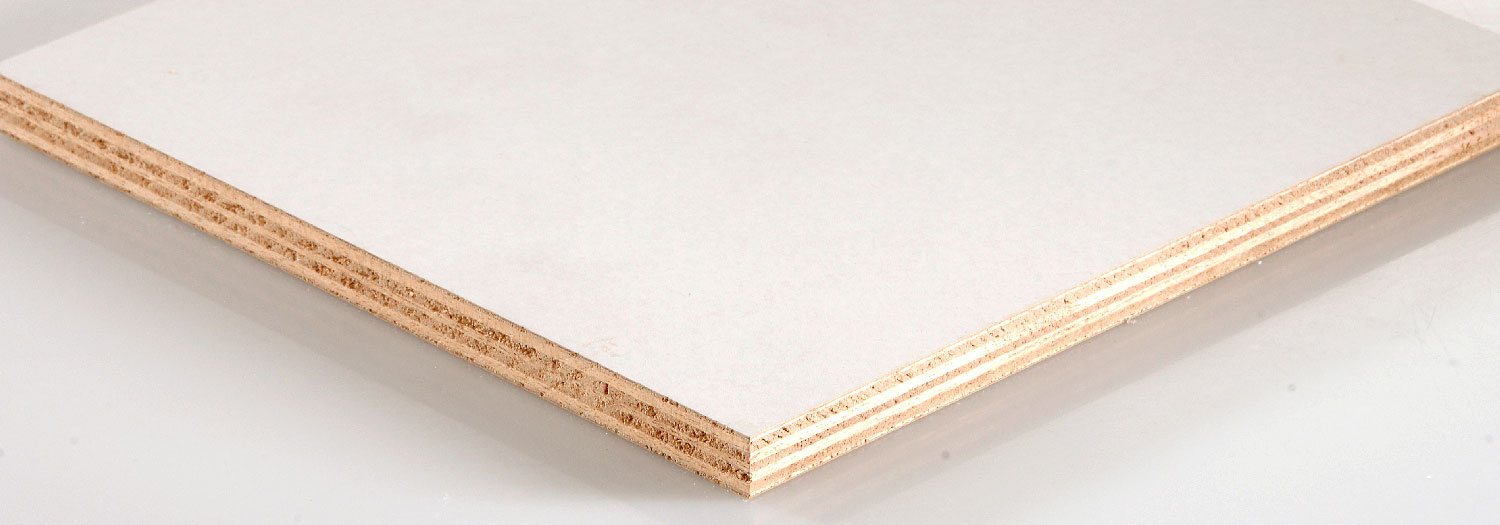

Rtp Plywood

RTP plywood is a Medium Density Overlay (MDO) film faced Okoume plywood. It is specially manufactured to provide durability end longevity. Its physical characteristics are very stable and can withstand exposure to severe weather conditions for prolonged periods of time.

Performances and applications

RTP Plywood, with its film faced surfaces is a ready to paint panel, suitable for external and interior use as a structural component in the building industry.

Technical Specifications

General properties and tolerances (ex factory)

Thickness: 10 12 15 18 mm

Standard sizes: 2500 X 1220 mm, 3100 X 1520 mm

Squareness: ±0.25% of the length of the diagonal

Moisture content: between 6% and 10%

Density: 500 kg/cbm ±10%

Other properties

Glue line: Water and waterproof gluing using Melamine Urea Formaldehyde (MUF) and/or Phenol Formaldehyde (PF) resins. MDO film is bonded with Phenol Formaldehyde (PF) resins.

Face: Well selected BB/BB face veneers without defects, suitable for MDO film overlaying.

Core Veneers: They have the same basic requirements as face veneers, except that small splits may occur, and there is no limit on the number of pin knots or edge joints. Core veneer thickness is between 1,5 mm and 3,0 mm.

Finishing: Both sides are overlaid with an advanced primed and paintable Medium Density Overlay (MDO) film providing a smooth, uniform and light coloured surface. Colour options for each side are white/white, white/grey or grey/grey.

Performance characteristics and standards compliance

Standards: Meets the requirements of EN 13986:2004+A1.

Bonding quality: Class 3 (EN 314-2)

Durability (humidity): Class 3S - External use as structural components (EN 636)

Formaldehyde class: E1

Reaction to fire: class D-s2, d0

Certifications

CE 2+ SKH No. 0502-CPR 10133

Lloyd’s Register Type Approval No. 05/00052

KOMO No.32711/15

FSC C007917

ISO 9001:2008

HellasSites

HellasSites